DJI Mavic 4 Pro Crashes 8 Seconds After Takeoff: Why Even Flagship Drones Need Hover Tests

A DJI Mavic 4 Pro, DJI’s newest flagship drone, suffered catastrophic propeller failure just eight seconds into a hover test, crashing from approximately 10 feet and breaking an arm. The drone incident serves as a stark reminder that even high-end drones can fail without warning, and that pre-flight inspections alone aren’t enough to guarantee safe operations.

The crash underscores a critical safety practice many pilots overlook: the post-takeoff hover test. While DJI has built a reputation for reliable, user-friendly drones, this incident proves that complacency can be dangerous—and expensive.

What Happened During the Mavic 4 Pro Crash

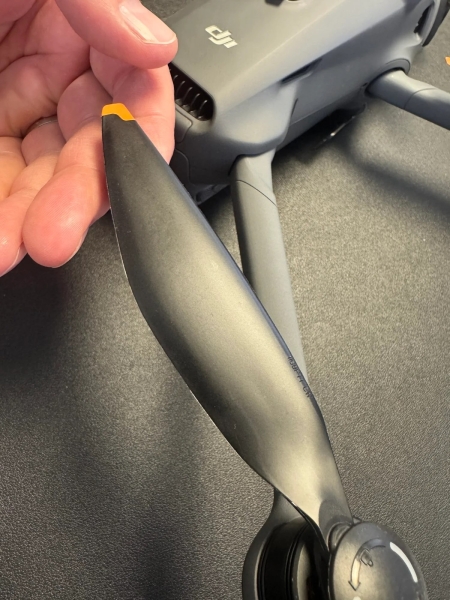

The pilot was conducting what should have been a routine hover test before filming content at Niagara Falls—a shoot that had taken two weeks to coordinate. After performing a standard pre-flight inspection that included visually examining the drone and running hands over the propeller blades, the pilot launched the Mavic 4 Pro.

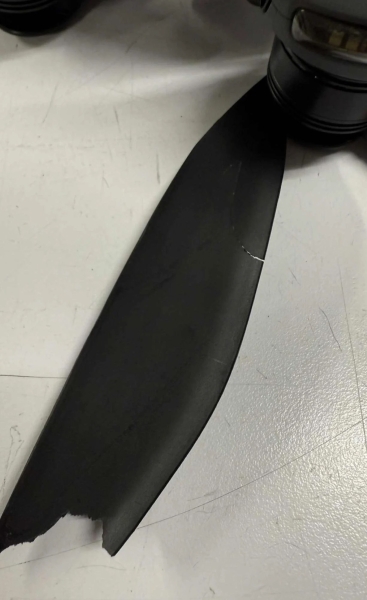

Within eight seconds of takeoff, while hovering at approximately 2.8 meters (9 feet), the pilot heard a distinct “pop.” The drone immediately lost control and fell to the ground, breaking one of the arms in the process. Post-crash examination revealed a crack in one of the propeller blades that had apparently failed mid-flight—though it’s unclear whether the crack existed before takeoff or developed during the brief flight.

“In all my years and all the drones we’re flown, I was with my most experienced pilot. We’ve never seen anything like this,” the pilot reported in private messages about the incident.

The timing proved fortunate—the drone was still low to the ground during testing rather than at altitude during an active shoot. Nobody was standing beneath the aircraft, and the pilot had a backup Mavic 4 on hand to complete the mission.

The Mavic 4 Pro’s Troubled Launch History

The DJI Mavic 4 Pro launched on May 13, 2025, after delays from its originally planned April 24 release date. The delays stemmed from issues with the drone’s new electronic ND filter system and fast-charging battery, with early units reportedly showing inconsistent performance during retailer testing.

The Mavic 4 Pro represents DJI’s most advanced consumer drone to date, featuring a 100-megapixel Hasselblad camera, triple-camera system with 28mm, 70mm, and 168mm focal lengths, 51-minute flight time, and sophisticated obstacle avoidance. With pricing starting at $2,250 and reaching $4,400 for the Creator Combo, it’s positioned as the pinnacle of consumer aerial technology.

Yet even with all that engineering sophistication, a simple propeller failure brought it down in seconds.

Why Propeller Failures Happen to All Drones

Propeller failures, while uncommon, have plagued drones across all manufacturers and price points. The UK’s Air Accidents Investigation Branch investigated a DJI Phantom 4 RTK crash in 2020 where a propeller detached mid-flight at 70 meters (230 feet). The report calculated the impact energy at 900 Joules—enough to cause fatal injury if someone had been struck.

DJI itself acknowledged that incident but stated they had “currently not seen any recurring pattern of similar cases.” However, drone forums and pilot communities tell a different story, with scattered reports of propeller failures across DJI’s product line dating back years.

Common causes include:

- Manufacturing defects: Microscopic cracks in the propeller hub or blade that aren’t visible during inspection

- Material fatigue: Propellers weaken over time from repeated stress, even without visible damage

- Installation errors: Improperly seated quick-release propellers can detach or fail

- Impact damage: Minor strikes against grass, branches, or other objects that create hidden structural compromise

- Extreme conditions: Temperature fluctuations, UV exposure, and moisture can degrade propeller materials

The challenge for pilots is that many of these failure modes aren’t detectable during standard pre-flight visual inspections. A propeller can look perfect yet harbor internal stress fractures that fail under flight loads.

The Critical Importance of Hover Tests

This incident highlights why experienced pilots perform post-takeoff hover tests before executing their mission. DroneXL recommends hovering close to the ground for 20 seconds after takeoff, looking and listening for drone defects before climbing to altitude.

A proper hover test should include:

- Low altitude hovering (3-10 feet) for 15-30 seconds

- Listening for unusual motor sounds, vibrations, or propeller noise

- Visual inspection of flight stability—any wobbling, drifting, or erratic behavior

- Control testing by gently moving the sticks in all directions to verify responsive control

- Motor sound check by listening for any motors working harder than others

If the Mavic 4 Pro’s propeller had been fully compromised before takeoff, the hover test caught it at the safest possible altitude. Had the pilot skipped this step and climbed immediately to 100+ feet for the Niagara Falls shoot, the outcome could have been far worse—potentially injuring bystanders below or destroying the drone and weeks of planning.

Pre-Flight Inspections: Necessary But Not Sufficient

The FAA requires drone operators under Part 107 regulations to conduct pre-flight inspections assessing the operating environment, ensuring control links function properly, verifying sufficient power, and confirming secure payloads. Yet even rigorous pre-flight checks can’t catch every failure mode.

According to DJI’s own guidance, operators should check each rotor before flight to ensure they’re in perfect shape, as propellers are “quite susceptible to bending out of shape after several bumps.” The company recommends inspecting for cracks, chips, warping, or any signs of damage.

But as this DJI Mavic 4 Pro incident demonstrates, visual inspection has limits. Some propeller failures involve internal stress fractures, hub cracks, or material degradation that isn’t visible to the naked eye. Even running your fingers along the blade edges—as this pilot did—may not detect microscopic damage.

This is precisely why the aviation industry has long emphasized the importance of redundant safety measures. Pre-flight inspections catch obvious problems. Post-takeoff hover tests catch hidden ones before they become catastrophic.

The Complacency Problem: When Reliability Breeds Carelessness

DJI has earned its dominant market position partly through exceptional reliability. Modern DJI drones feature sophisticated flight controllers, redundant sensors, and safety systems that make them remarkably stable and forgiving. This has led many pilots—recreational and professional alike—to develop a dangerous level of trust.

“Many people don’t test anything and just send the drone,” one drone operator noted in discussions about the incident, acknowledging the widespread tendency to skip hover tests entirely.

This complacency is understandable but misguided. Every drone, regardless of manufacturer or price point, relies on mechanical components subject to failure. Motors can overheat, propellers can crack, batteries can develop faults, and electronic systems can glitch. The more we trust technology to be infallible, the more vulnerable we become when it inevitably fails.

The DJI Mavic 4 Pro can cost up to $4,400 and represents the cutting edge of consumer drone technology. Yet it failed eight seconds into flight. If it can happen to DJI’s flagship, it can happen to any drone.

DroneXL’s Take on the DJI Mavic 4 Pro Crash

We’ve spent years covering drone technology at DroneXL, watching the industry mature from experimental toys into sophisticated aerial platforms. We’ve reported on Amazon’s Prime Air crashes caused by sensor failures, Skydio X10 battery connector issues, and now this DJI Mavic 4 Pro propeller failure. Each incident reinforces the same fundamental lesson: there is no such thing as a failure-proof drone.

What strikes us most about this incident is how easily it could have been catastrophic. If the propeller had failed 30 seconds later when the drone was at 100 feet over Niagara Falls, the outcome would have been dramatically different. The drone likely would have been destroyed. If it had fallen into the crowd below, someone could have been seriously injured or killed. A 1,063-gram drone falling from that height carries lethal kinetic energy.

The pilot’s decision to conduct a low-altitude hover test before ascending to working altitude quite literally saved the mission—and possibly prevented a tragedy.

This raises uncomfortable questions about how we approach drone safety in the age of increasingly capable consumer aircraft. Are we becoming too complacent? Are we trusting DJI’s reputation for reliability more than we trust basic safety protocols? When was the last time you conducted a proper hover test before climbing to altitude?

The drone industry has made remarkable progress in reliability and safety systems. But mechanical components still fail. Propellers still crack. And gravity still works the same way it always has. No amount of sophisticated flight control algorithms can keep a drone airborne when a propeller disintegrates.

The good news is that proper pre-flight procedures and post-takeoff hover tests are simple, free, and effective. They take less than a minute but can save thousands of dollars in equipment and prevent potential injuries. In this case, they absolutely did.

As drones become more capable and reliable, we can’t allow ourselves to become less vigilant. If anything, the opposite should be true. The more we depend on these aircraft for professional work, creative projects, and critical operations, the more important it becomes to treat them with the respect they deserve as flying machines subject to mechanical failure.

We want to hear from you: What’s your pre-flight inspection routine? Do you conduct hover tests before every flight? Have you ever caught a problem during a hover test that could have turned into a crash? Share your pre-flight checklist and safety practices in the comments below to help fellow pilots minimize risk and keep their drones in good working order.